Mis va temir po'lat uchun bar va rodning induksion zarb uchi

Tavsif

Mis, alyuminiy va temir po'lat uchun novda va rodning induksion zarb uchi

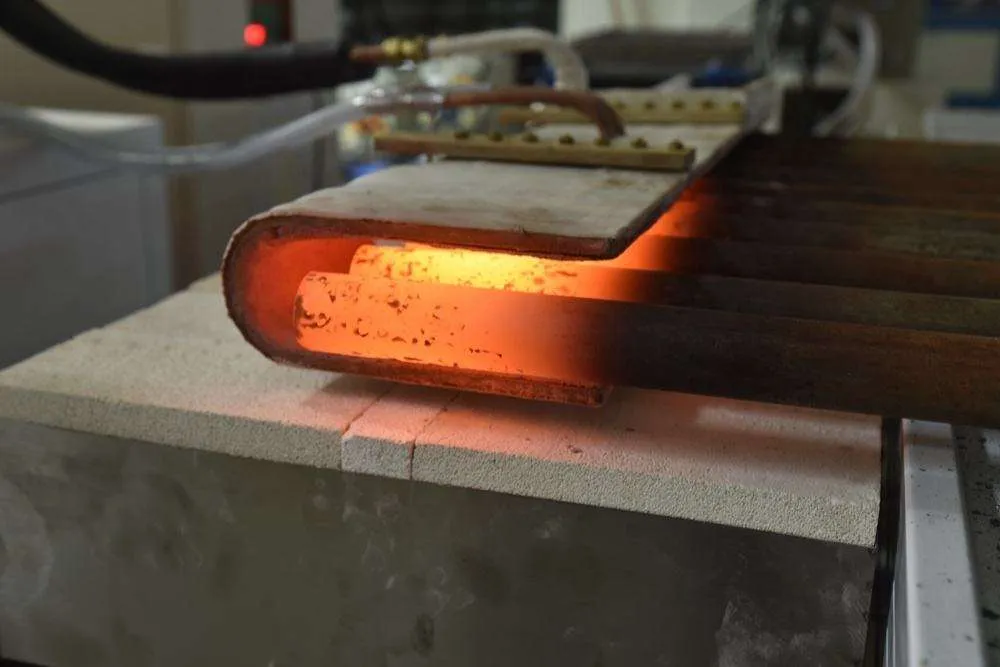

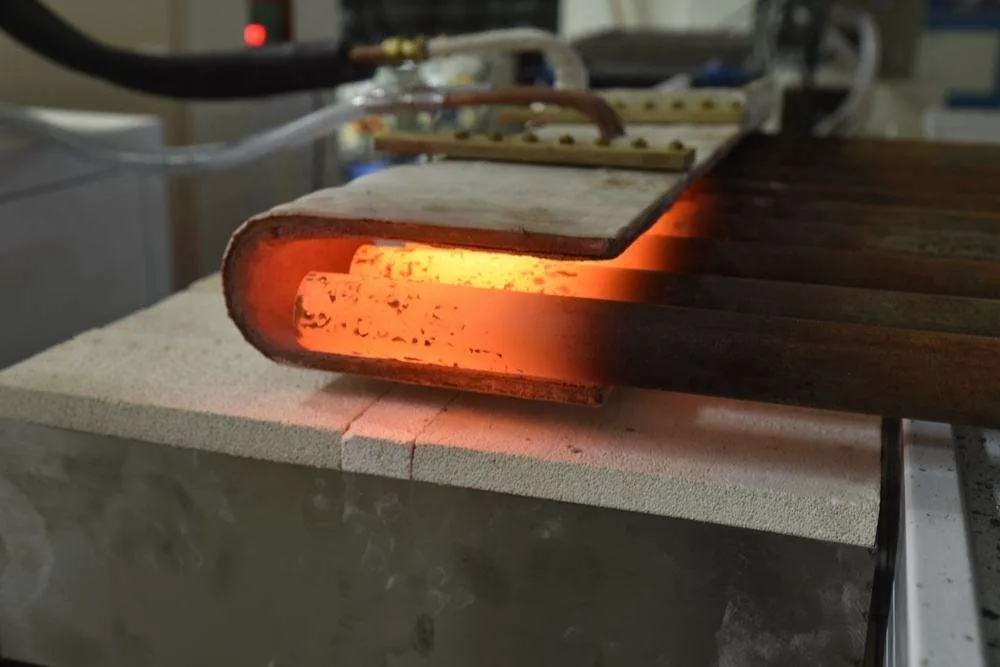

Indüksiyon zarb qilish: press yoki bolg'a yordamida deformatsiyadan oldin metallarni oldindan qizdirish uchun induksion isitgichdan foydalanishni nazarda tutadi. Odatda metallar 1,100 °C (2,010 °F) va 1,200 °C (2,190 °F) gacha isitiladi, bu ularning egiluvchanligini oshirish va zarb qolipidagi oqimga yordam beradi.

Indüksiyon zarb qilish: press yoki bolg'a yordamida deformatsiyadan oldin metallarni oldindan qizdirish uchun induksion isitgichdan foydalanishni nazarda tutadi. Odatda metallar 1,100 °C (2,010 °F) va 1,200 °C (2,190 °F) gacha isitiladi, bu ularning egiluvchanligini oshirish va zarb qolipidagi oqimga yordam beradi.

jarayoni: Induksion isitish ishlov beriladigan qismda issiqlik hosil qilish uchun elektromagnit induksiya printsipidan foydalanadigan kontaktsiz jarayondir. Supero'tkazuvchi materialni kuchli o'zgaruvchan magnit maydonga joylashtirish orqali elektr toki materialda oqib o'tadi va shu bilan Joule isishiga olib keladi. Magnit materiallarda histerezis yo'qotishlari tufayli Kyuri nuqtasi ostida qo'shimcha issiqlik hosil bo'ladi. Yaratilgan oqim asosan sirt qatlamida oqadi, bu qatlamning chuqurligi o'zgaruvchan maydonning chastotasi va materialning o'tkazuvchanligi bilan belgilanadi.

afzalliklari:

■ Jarayonni boshqarish imkoniyati

■ Energiya samaradorligi

■ Haroratning tez ko'tarilishi

■ Jarayonning izchilligi

Ilova: Mis tayoqchalar, temir tayoqchalar va turli shakldagi alyuminiy rodlar diatermiyasi uchun javob beradi. Ish qismini to'liq yoki mahalliy isitish mumkin.

Asosiy ilovalar:

Rod pechining induksion zarb uchi vintlardek, yong'oqlar, klapanlar, qulflar va boshqa metall qismlarni shakllantirishda PH12 mm dan kattaroq bar va novdalarni isitish uchun ishlatiladi, material po'lat, zanglamaydigan po'lat, mis, guruch, bronza, alyuminiy va Shunday qilib, isitish butun isitish va qisman isitish bo'lishi mumkin, masalan, oxirgi isitish yoki o'rta qismni isitish.

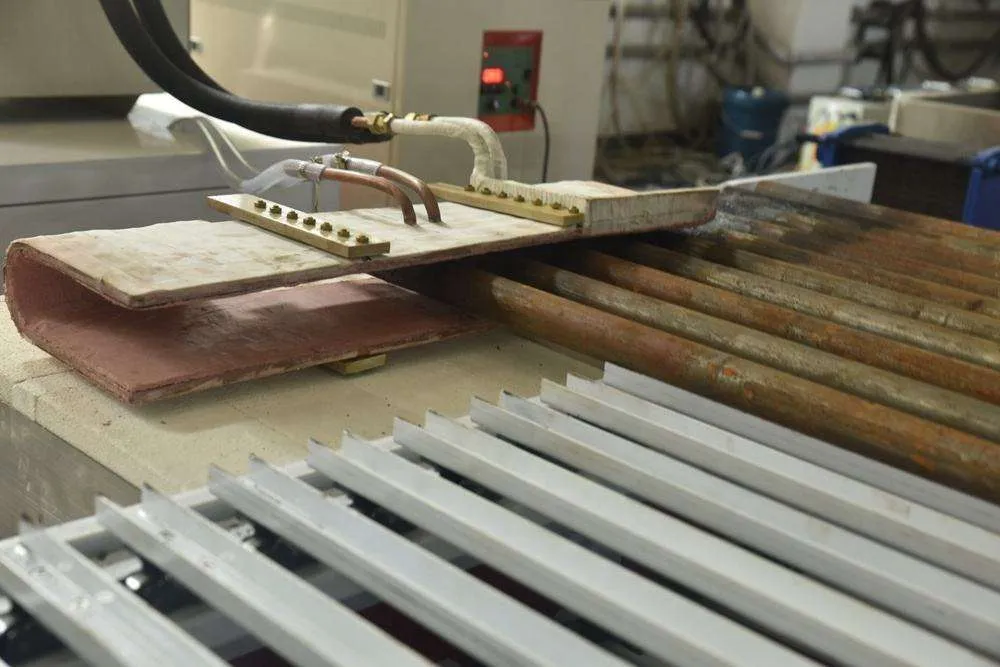

Induksion zarb pechining tarkibi:

Induksion zarb pechining tarkibi:

- Induksion isitish quvvat manbai.

- Induksion isitish batareyasi va hidoyat ray va lasan qopqog'i.

- pnevmatik novda oziqlantiruvchi.

- nazorat qilish tizimi.

- suv sovutish tizimi.

Ba'zi ilovalar uchun, agar buyurtma bo'lsa, infraqizil harorat sensori, harorat sozlagichi va avtomatik novda oziqlantirish tizimlari ham kiritilishi mumkin.

Asosiy modellar va isitish qobiliyati:

| modellar | Maksimal kirish kuchi | Ilovani tavsiya eting | Oddiy materialni isitish qobiliyati | |

| Chelik yoki zanglamaydigan po'latdan 1200 ℃ gacha | Mis yoki guruch 700 ℃ gacha | |||

| MF-35 induksion zarb pechi | 35KW | PH15-30 novda isitish | 1.25KG/min | 1.75KG/min |

| MF-45 induksion zarb pechi | 45KW | 1.67KG/min | 2.33KG/min | |

| MF-70 induksion zarb pechi | 70KW | PH15-50 novda isitish | 2.5KG/min | 3.5KG/min |

| MF-90 induksion zarb pechi | 90KW | PH25-50 novda isitish | 3.33KG/min | 4.67KG/min |

| MF-110 induksion zarb pechi | 110KW | 4.17KG/min | 5.83KG/min | |

| MF-160 induksion zarb pechi | 160KW | PH50 dan yuqori novda isitish | 5.83KG/min | 8.26KG/min |

Asosiy modellar va isitish qobiliyati:

Asosiy modellar va isitish qobiliyati:

| modellar | Quvvat | Ilovani tavsiya eting | Chelik yoki zanglamaydigan po'latdan 1200 ℃, KG / soatgacha isitish quvvati | Misni 700 ℃, KG/soatgacha isitish quvvati | |

| SF-40AB | 40KW | PH15-40 mm novda isitish | 110 kg / soat | 190 kg / soat | |

| SF-50AB | 50KW | PH15-40 mm novda isitish | 137 kg / soat | 237 kg / soat | |

| SF-60AB | 60KW | PH15-40 mm novda isitish | 160 kg / soat | 290 kg / soat | |

| SF-80AB | 80KW | PH15-40 mm novda isitish | 165 kg / soat | 380 kg / soat | |

| SF-100AB | 100KW | PH15-40 mm novda isitish | 275 kg / soat | 480 kg / soat | |

| SF-120AB | 120KW | PH15-40 mm novda isitish | 275 kg / soat | 480 kg / soat | |

| SF-120AB | 120KW | PH15-40 mm novda isitish | 330 kg / soat | 570 kg / soat | |

| SF-160AB | 160KW | PH15-40 mm novda isitish | 440 kg / soat | 770 kg / soat | |

| SF-200AB | 200KW | PH15-40 mm novda isitish | 550 kg / soat | 960 kg / soat | |

| SF-250AB | 250KW | PH15-40 mm novda isitish | 690 kg / soat | 1180 kg / soat | |

| MFS-200 yoki D-MFS200 | 200KW | PH40 dan yuqori novda isitish | 550 kg / soat | 960 kg / soat | |

| MFS-250 yoki D-MFS250 | 250KW | 690 kg / soat | 1180 kg / soat | ||

| MFS-300 yoki D-MFS300 | 300KW | 830 kg / soat | 1440 kg / soat | ||

| MFS-400 yoki D-MFS400 | 400KW | 1100 kg / soat | 1880 kg / soat | ||

| MFS-500 yoki D-MFS500 | 500KW | 1380 kg / soat | 2350 kg / soat | ||

| MFS-600 yoki D-MFS500 | 600KW | 1660 kg / soat | 2820 kg / soat | ||

| MFS-750 yoki D-MFS750 | 750KW | 2070 kg / soat | 3525 kg / soat | ||

| MFS-800 yoki D-MFS800 | 800KW | 2210 kg / soat | 3700 kg / soat | ||

| MFS-1000 yoki D-MFS1000 | 1000KW | 2750 kg / soat | 4820 kg / soat | ||

| MFS-1200 yoki D-MFS1200 | 1200KW | 3300 kg / soat | 5780 kg / soat | ||

| MFS-1500 yoki D-MFS1500 | 1500KW | 4200 kg / soat | 7200 kg / soat | ||

| MFS-2000 yoki D-MFS2000 | 2000KW | 5500 kg / soat | 9600 kg / soat |